Kukhazikitsa koyenera kwavalavu ya gulugufendi yofunika kwambiri pakugwira ntchito kwake kotseka komanso nthawi yogwira ntchito. Chikalatachi chikufotokoza mwatsatanetsatane njira zoyikira, mfundo zazikulu, ndikuwonetsa kusiyana pakati pa mitundu iwiri yodziwika bwino: wafer-style ndimavavu a gulugufe opindikaMa valve opangidwa ngati wafer, omwe amaikidwa pakati pa ma flange awiri a mapaipi pogwiritsa ntchito ma stud bolts, ali ndi njira yovuta kwambiri yoyikira. Mosiyana ndi zimenezi, ma valve a gulugufe opangidwa ndi flanges amabwera ndi ma flanges ofunikira ndipo amamangiriridwa mwachindunji ku ma flanges a mapaipi ogwirizana, zomwe zimapangitsa kuti ntchitoyi ikhale yosavuta.

Maboluti a flange a valavu ya gulugufe wa wafer ndi aatali pang'ono. Kutalika kwawo kumawerengedwa motere: makulidwe a flange awiri + makulidwe a valavu + makulidwe a mtedza awiri. Izi zili choncho chifukwa valavu ya gulugufe wa wafer yokha ilibe ma flange. Ngati ma boluti ndi mtedza awa achotsedwa, mapaipi mbali zonse ziwiri za valavu adzasokonekera ndipo sangathe kugwira ntchito bwino.

Ma valve opindika amagwiritsa ntchito mabolt afupiafupi, okhala ndi kutalika kotchulidwa kuti makulidwe a flange awiri + makulidwe a nati awiri, kuti alumikize ma flange a valavu mwachindunji ndi omwe ali pa payipi. Ubwino waukulu wa kapangidwe kameneka ndikuti amalola kuti mbali imodzi idulidwe popanda kusokoneza ntchito ya payipi yotsutsana.

Nkhaniyi ifotokoza makamaka malangizo okhazikitsa ma valve a gulugufe a wafer pogwiritsa ntchitoTWS.

Valavu ya gulugufe ya wafer ili ndi kapangidwe kosavuta, kakang'ono, komanso kopepuka kokhala ndi zigawo zochepa kwambiri. Imagwira ntchito ndi kuzungulira mwachangu kwa 90°, zomwe zimathandiza kuti ikhale yosavuta kuyiyatsa/kuimitsa komanso kupereka njira yabwino kwambiri yoyendetsera kayendedwe ka madzi.

I. Malangizo MusanayikeVavu ya Gulugufe Yokhala ndi Mtundu Wokulungika

- Musanayambe kukhazikitsa, payipi iyenera kuchotsedwa zinthu zilizonse zakunja pogwiritsa ntchito mpweya wopanikizika kenako n’kuyeretsedwa ndi madzi oyera.

- Onetsetsani mosamala ngati kugwiritsa ntchito valavu kukugwirizana ndi momwe imagwirira ntchito (kutentha, kuthamanga).

- Yang'anani njira ya valavu ndi malo otsekeramo kuti muwone ngati pali zinyalala, ndipo zichotseni mwachangu.

- Mukatsegula, valavu iyenera kuyikidwa mwachangu. Musamasule zomangira kapena nati zilizonse zomangira valavu mwachisawawa.

- Chovala chapadera cha gulugufe chiyenera kugwiritsidwa ntchito pa mavavu a gulugufe amtundu wa wafer.

- Thevalavu yamagetsi ya gulugufeikhoza kuyikidwa pa mapaipi mbali iliyonse, koma kuti kukonza kukhale kosavuta, ndibwino kuti musayike mozondoka.

- Mukayika flange ya valavu ya gulugufe, ndikofunikira kuonetsetsa kuti nkhope ya flange ndi rabala yotsekera zikugwirizana, mabotolo amangika mofanana, ndipo pamwamba pake potsekera payenera kukhala bwino. Ngati mabotolo sanangike mofanana, izi zingayambitse kuti rabala itukuke ndikutseka diski, kapena kukankhira diski, zomwe zimapangitsa kuti tsinde la valavu lituluke.

II.Kukhazikitsa: Valavu ya Gulugufe Wafer

Kuti muwonetsetse kuti valavu ya gulugufe siikutuluka madzi komanso kuti ikugwira ntchito bwino komanso motetezeka, tsatirani njira yoyikira yomwe ili pansipa.

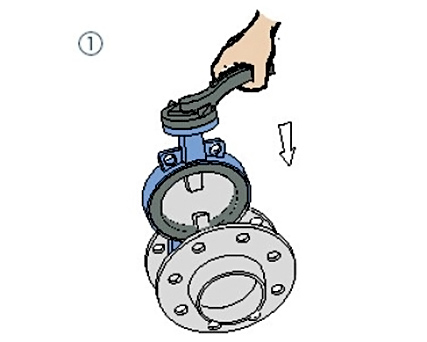

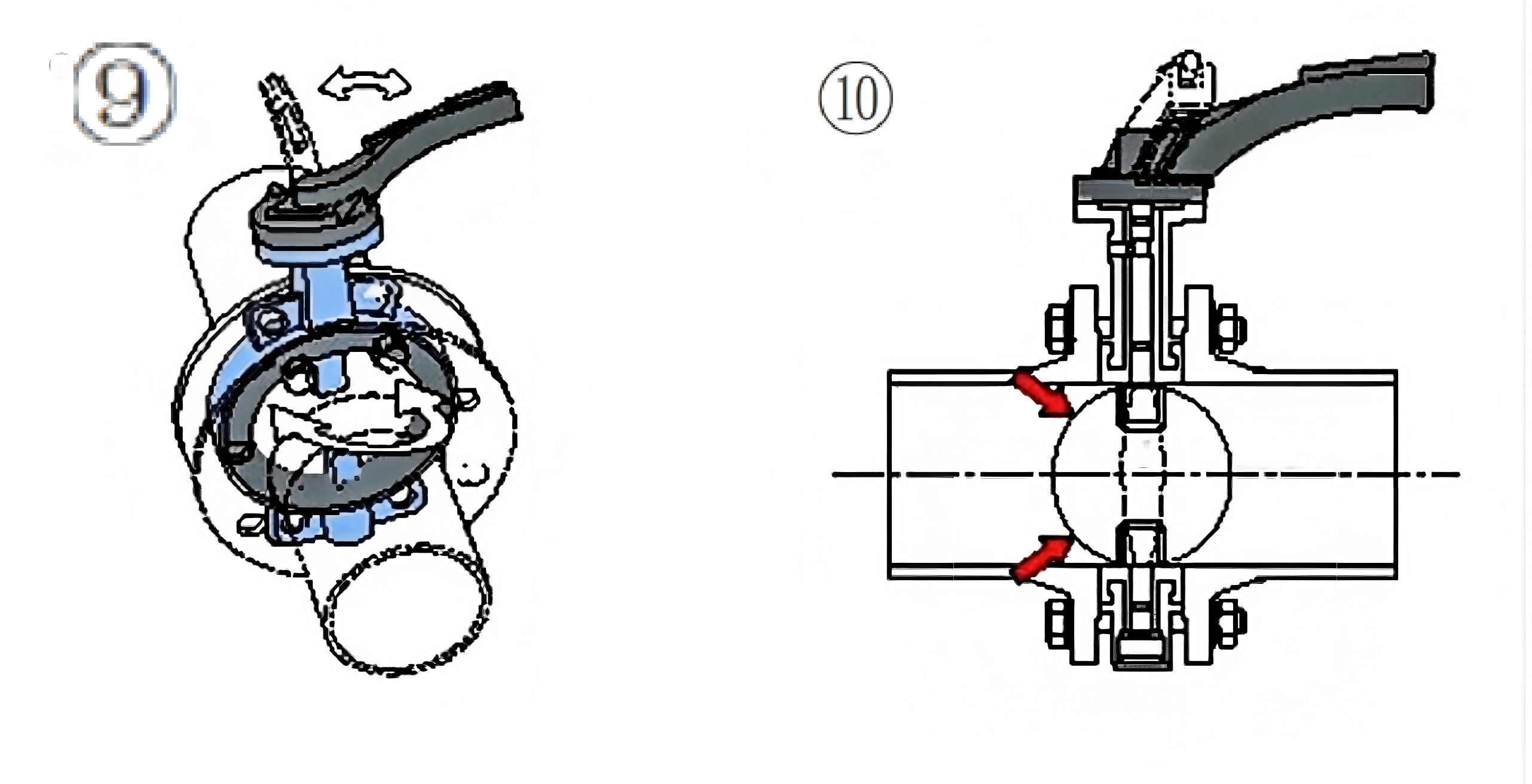

1. Monga momwe zasonyezedwera, ikani valavu pakati pa ma flange awiri omwe adayikidwa kale, ndikuwonetsetsa kuti mabowo a bolt ali bwino.

2. Ikani pang'onopang'ono ma bolts ndi mtedza m'mabowo a flange, ndipo limbitsani pang'ono mtedzawo kuti mukonze kusalala kwa pamwamba pa flange;

3. Gwiritsani ntchito chowotcherera cha spot kuti mulumikize flange ku payipi.

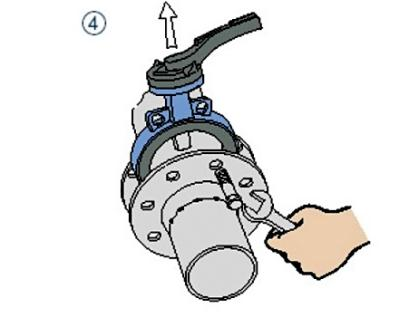

4. Chotsani valavu;

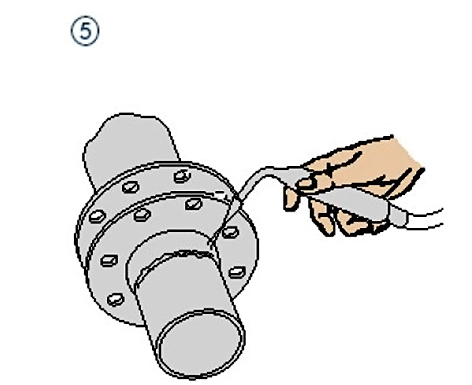

5. Kulukana bwino flange kupita ku payipi.

6. Ikani valavu pokhapokha cholumikizira cholumikizidwa chitazizira. Onetsetsani kuti valavu ili ndi malo okwanira oti iyende mkati mwa flange kuti isawonongeke komanso kuti valavuyo itsegule pamlingo winawake.

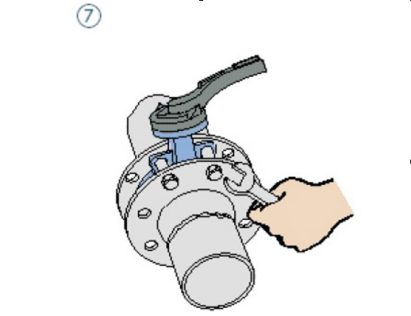

7. Sinthani malo a valavu ndikulimbitsa ma bolts anayi (samalani kuti musamangitse kwambiri).

8. Tsegulani valavu kuti muwonetsetse kuti diski ikhoza kuyenda momasuka, kenako tsegulani diski pang'ono.

9. Gwiritsani ntchito chitsanzo chopingasa kuti mumange mtedza wonse.

10. Tsimikiziraninso kuti valavu ikhoza kutseguka ndi kutsekedwa momasuka. Dziwani: Onetsetsani kuti diski ya valavu sikhudza payipi.

Kuti ma valve a gulugufe a wafer asatuluke komanso asatuluke madzi, tsatirani mfundo izi:

- Chogwirira Mosamala: Sungani valavu mosamala ndipo pewani kugundana.

- Lumikizani Molondola: Onetsetsani kuti flange ikugwirizana bwino kuti mupewe kutayikira.

- Musamasule: Mukayika, valavu siyenera kuchotsedwa m'munda.

- Ikani Zothandizira Zokhazikika: Mangani valavu ndi zothandizira zomwe ziyenera kukhala pamalo pake.

TWSimapereka ma valve apamwamba a gulugufe komanso mayankho athunthu avalavu ya chipata, valavu yoyezerandimavavu otulutsa mpweyaLumikizanani nafe ngati mukufuna zonse zokhudza ma valvu anu.

Nthawi yotumizira: Novembala-08-2025